- Home

-

Products

-

HF Series RFID Products

-

HF Integrated Reader

-

Product Model

- SG-HR-I1 HF Integrated Reader SG-HR-I2 HF Integrated Reader SG-HR-I5 HF Integrated Reader SG-HR-I6 HF Integrated Reader SG-HR-I10 HF Integrated Reader

-

HF Split Read-write Processor/Split Antenna

-

Product Model

- SG-HA-181/182 HF RFID ANTENNA SG-HA-183 HF Middle Range RFID Reader SG-HR-S1 Universal Fixed RFID Reader SG-HR-S6 Series SG-HR-S8 Series

-

Product Model

-

UHF Series RFID Products

-

UHF Integrated Reader

-

Product Model

- SG-UR-I81 UHF Integrated Reader SG-UR-I82 UHF Integrated Reader SG-UR-I83 UHF Integrated Reader SG-UR-I84 UHF Integrated Reader SG-UR-I85 UHF Integrated Reader SG-UR-I86 UHF Integrated Reader

-

UHF Split Read-write Processor/Split Antenna

-

Product Model

- SG-UR-A9 UHF Split Reader SG-UR-A10 Multi-Channel UHF Read/Write Devices(860~960MHz) SG-UR-A12 Multi-Channel UHF Read/Write Devices(860~928MHz) SG-UR-A16 Multi-Channel UHF Read/Write Devices(860~928MHz) SG-UA-271 UHF Small Universal Antenna UHF Antenna SG-UA-273 UHF Antenna SG-UA-274

-

Product Model

- Industrial Bus Gateway Module

- Industrial Code Reader

-

HF Series RFID Products

- Equipment

- Industry & Case

- News

- Service

- Company

- Details

Product Advantages

üFunction

●Operating frequency is 13.56MHz,in line with ISO-15693 standard

●Support RS-232/RS-485 communication mode

●One-piece design,compact structure,convenient for distributed installation and deployment

üPerformance

●With IP67 protection grade can adapt to harsh environments such as oil (cutting fluid,etc.),dust,moisture,etc.

●Efficient data collection capability can effectively improve the accuracy of data collection in MES systems.

●The interface uses a 5/8-pin industrial aviation plug (male)/threaded connector to ensure connection in vibration environment.

●Built-in filtering and isolation module,they have strong anti-interference ability to EMC.

üApplication:

Power battery production line,Automobile production line,Household appliances /3C mixed flow production line,AGV,etc.

üTypical Application:

²Engine Assembly Line

The reader can interface with various PLCs such as Siemens,Schneider and Mitsubishi through the industrial bus controller. By reading the RFID tag mounted on the tray,passing the information to the PLC, Through the information of installation to guide the assembly robot or the assembler to auto select the appropriate part,the engine assembly efficiency can be greatly improved.

²Power Battery Assembly

Install the SG-HR-I2 reader at the RFID collection point, and the on-line station collection point reads the RFID tag in the material box to obtain the information of slots in the material box (each slot is equipped with a cell with different voltage), The voltage value/grade of the test cell is written into the material box RFID tag at the test station of the voltage cell. When the cell is classified, read the RFID tag information of the material box and connect the robot in real time to automaticaly put the cell into the corresponding cell transport track. After the robot takes down the cell with different gear from the transport track and puts them into the same material box it will write the cell gear information into the RFID tag of the material box. Through the operation of each station on the RFID tag, a series of processes such as cell division, transportation, encapsulation, and assembly are completed in the process of cell assembly.

²Intelligent Application of Home Appliance Manufacturing Process

Through RFID data acquisition technology (By adding RFID tags on the product/tooling board and deploying RFID readers on the workstation),the unmanned,automatic and real-time identification of single-item products on the production line is realized.

Using real-time collected product information,complete error prevention of mixed flow production materials,real-time push of process guidance,automatic diversion of defective products,automatic generation of quality reports,product traceability management,mixed flow line alarms,and equipment automation docking.

Technical Parameters

Specifications | Wireless protocol | ISO-15693 |

Working frequency | 13.56MHz | |

Output power | 23dBm | |

Wireless rate | 26.5kbit/s | |

Read/write distance | 0-60mm(related to antennas and tags) | |

Communication Port | RS232 or RS485 | |

Communication rate | 115.2kbit/s | |

Power voltage | 24VDC +/-10% | |

Current | <0.05A@24VDC | |

Indicator light | 1 led indicators | |

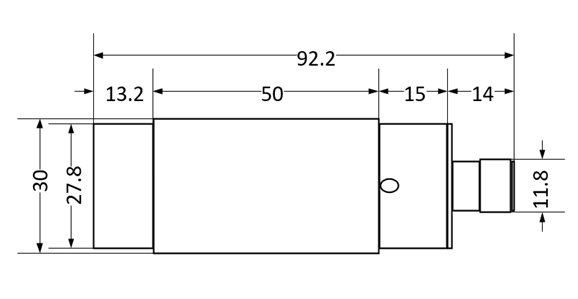

Physical parameters | Size | φ30*92.2mm |

Weight | 0.11kg | |

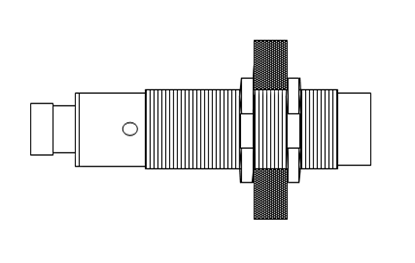

Fixed type | Nut fixing | |

Housing material | Brass nickel plating | |

Shell color | Black+Sliver | |

Connector | A-CODE M12 | |

Application environment | Working Temperature | -40℃~+70℃ |

Storage Temperature | -40℃~+85℃ | |

Humidity | 5%~95%RH(no condensation) | |

Waterproof/dustproof | IP67 | |

Drop experiment | GB/T2423.8-1995 | |

Impact resistance | GB/T2423.10-2008 | |

Certification | CE、RoHS2.0 | |

Accessories |

Dimension Drawing(mm)

Way of Installation

²Installation of the readers

The product comes with M30*1.5 thread. When fixing, use two nuts to clamp on the bracket.

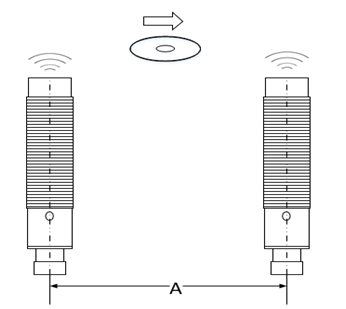

²The distance between two readers

When there are multiple readers to be installed, the distance between the readers needs to be greater than 100MM.

²Installation of the Tags

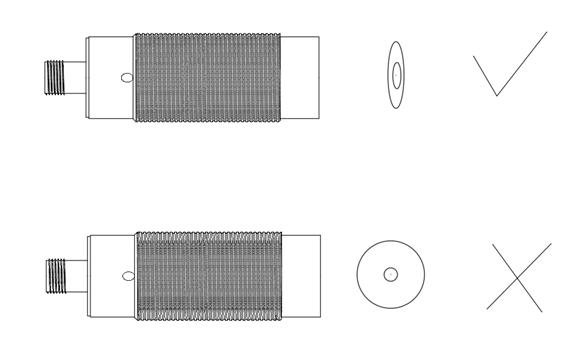

When installing the tag, it is necessary to make the sensing surface of the reader parallel to the front of the tag.