Military industry needs

Aerospace and military manufacturing represent the country ’s high-end manufacturing and cutting-edge technology, as well as a symbol of the country ’s comprehensive scientific and technological strength, and are China ’s main force for manufacturing. Compared with other industries, the technical indicators, quality, cost, and delivery time of aerospace and military industrial product development and production processes have put forward more stringent requirements. Its small batch, multi-variety, zero defect, high safety, mixed flow production The characteristics also bring greater challenges to manufacturing. The new era of national defense construction has put forward urgent needs for the development of the aerospace and military industries. The implementation of intelligent manufacturing and digital transformation is the only way. It has also become an important part of Made in China 2025.

sygole solution:

As a leading national brand in the field of industrial perception, sygole closely follows the pace of national strategy and actively participates in military aviation and aerospace intelligent manufacturing and digital transformation. It provides intelligent warehouse management of military materials, intelligent tool management in processing and manufacturing processes, and intelligent production line data collection. Traceability solutions to meet the requirements of military single-piece mixed-flow manufacturing and high-quality quality monitoring. From C919 large passenger aircraft, ships, aerospace parts to military supplies, sygole is helping the national aerospace and military industry to intelligent manufacturing through the wisdom of the Internet of Things. In addition, sygole actively participates in major projects in the aerospace and military industries. Prospective sensing technology flexible electronics and ultra-high-speed visual inspection help the rapid development of the aerospace and military industries.

Application link:

1 Intelligent warehousing:

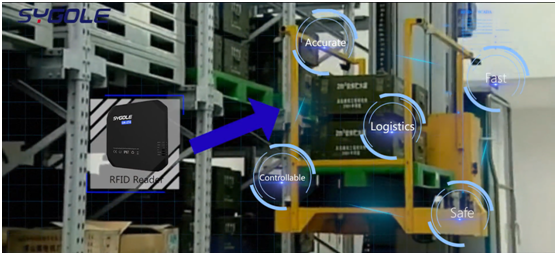

² Industry characteristics: The accuracy, speed, safety, and control of military warehousing and logistics are not only the role of support and support for modern military operations on the battlefield, but also determine the outcome of the war. The application of RFID technology has become an inevitable trend in the development of accurate, fast, safe, and controllable military logistics, and is bringing revolutionary changes to the management of military material supply chains.

² Customer pain points: Traditional military logistics processes are longer, more complicated to execute, and time-consuming and laborious to operate, making it difficult to meet the requirements of modern military operations.

² Solution: The material storage management system solution provided by sygole realizes the transparency of a series of circulation actions such as material storage, picking, distribution, nuclear and distribution, and improves the safety management efficiency of aerospace parts and combat readiness materials.

² Value gain: For the storage of materials in the military ’s fixed warehouse, it links the flow of materials between the upper and lower units to improve the efficiency of the safe management of combat readiness materials.

2 Tool management:

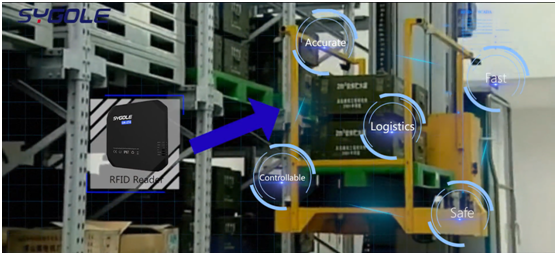

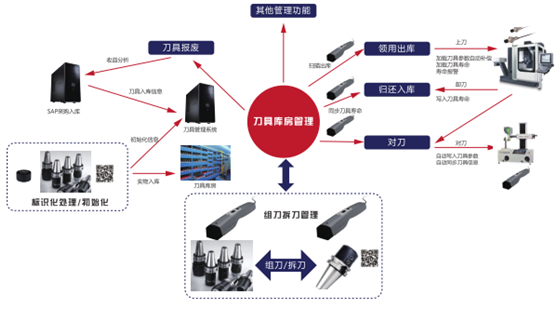

² Industry characteristics: The tool is an important production material for machining. In the process of building a digital workshop, military industrial enterprises should add such "dumb terminal" to the digital world through sensor technology, so as to realize the interconnection and intercommunication between terminals and equipment, and terminals and systems.

² Customer pain points: The number of tools in the machining production line is large, the warehouse management is difficult, and traceability is poor. Lots of quality problems and unplanned equipment downtime caused by poor tool management often occur.

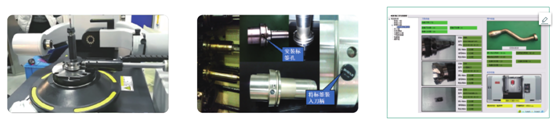

² Solution: sygole provides an RFID-based online tool detection and management system for the aerospace and military industries to achieve tool lifecycle management, improve tool utilization, increase efficiency, reduce error probability, and improve product processing quality.

² Value benefit: Achieve a 50% reduction in the quality defect rate caused by tools, a 30% reduction in tool reserves, a 20% reduction in tool costs per 10,000 yuan of production value, real-time data collection and transmission, data search and extraction time shortened by 50%, and work efficiency improved above 50.

3 Manufacturing traceability:

² Industry characteristics: The technical indicators and quality of the aerospace and military product development and production processes have put forward more stringent requirements, and its small batch, zero defect, high safety, and mixed flow production characteristics also bring greater production and manufacturing processes. Challenge.

² Customer pain points: Military production is demanding, and there are many product varieties and large amounts of data, resulting in difficult management and low production efficiency.

² Solution: The manufacturing equipment data collection system provided by sygole realizes real-time monitoring of equipment status, constructs information channels among equipment, systems and products, eliminates information islands of discrete operation units and improves production efficiency.

² Value benefit: realize error-free assembly of materials, automatic docking and recording of quality data, accurate traceability, visualization and real-time monitoring of production progress.

Typical application cases:

The "RFID+" solution provided by Sigu has been applied in many aerospace and military companies.