Logistics industry needs:

Logistics is the physical movement of material data from suppliers to demanders, and it is a unified whole of many basic activities such as transportation, storage, packaging, loading and unloading, circulation processing, distribution and information. Express logistics and pharmaceutical logistics are two major industries of modern logistics. Under the dual promotion of economic globalization and e-commerce, the rapid transformation from traditional logistics to modern logistics is an inevitable result. Under the development trend of intelligent logistics, it is the most essential feature of modern logistics to take the Internet of Things technology as the core and strengthen resource integration and optimization of the entire logistics process. As a systematic whole, the logistics industry is greatly changing the current business model and production model, and it is increasingly highlighting its important role and indispensable strategic position in economic development.

sygole solution:

sygole takes RFID technology as the core. By installing RFID tags on products and packaging containers as the only technical identification, it can trace the entire process in the logistics turnover process, and realize automatic identification of logistics points in the turnover process through RFID automatic identification equipment Improve the overall logistics efficiency, through RFID real-time information collection and information system is closely combined, timely understanding of logistics asset changes, improve logistics asset information timeliness.

Application link:

1 Express logistics:

² Industry characteristics: large turnover, high logistics cost, and difficult management.

² Customer pain points: Insufficient operation efficiency of packaging materials, large input of packaging materials and consumables, and high cost of personnel management.

² Solution: By installing RFID tags on packaging material containers, establishing RFID channel access control equipment for packaging material warehouses in the transit field, automatic reading of packaging materials / return containers and other materials in and out of the warehouse. Obtain the container inventory data of each transit site in time, realize the precise allocation of containers in the warehouse, and improve the efficiency of container use and overall logistics efficiency.

² Value benefit: Carry out refined management of various circulating containers used in logistics; establish container allocation with a data foundation to promote the rapid circulation of circulating containers; activate idle containers and reduce the overall input of containers; reduce the cost of production containers;

2 Pharmaceutical Logistics:

² Industry characteristics: There are many and small pharmaceutical wholesale enterprises; pharmaceutical wholesale lacks a unified code; the degree of automation is low and manual operation is the mainstay.。

² Customer pain points: The quality of drugs in storage and transportation is difficult to guarantee; logistics information lags, affecting drug supervision; manual operation data is inaccurate.

² Solution: The use of RFID technology for the production and circulation of medical products, the specific method of operation is: first of all, manufacturers, wholesalers, and retailers can use unique product codes to identify the identity of medical products. During the production process, an electronic label is affixed to each medical product. The electronic label records the unique product code number. The product code is determined before the production of the batch of products. After the production is completed, the batch number of the product is written to the electronic label. Complete the complete electronic code number of medical products as the only code for future distribution, sales and recycling. Logistic dealers, wholesalers, and retailers can strictly check the legality of products with RFID readers.

² Value benefit: Improve production efficiency, reduce labor cost, shorten product quality inspection time, monitor all situations of product manufacturing process in real time, quickly respond to the market, and reduce the loss of quantity of expired products.

ü Typical case-A

Project Background:

As an important indicator of the logistics industry, logistics efficiency is a comprehensive reflection of the market competitiveness of logistics enterprises. A Technology intends to use RFID technology to realize the rapid identification of logistics transfer points, reduce the storage time of logistics, and realize the rapid transfer of logistics items into and out, thereby improving the overall logistics efficiency and reducing logistics input costs.

An Introduction:

The project takes sygole's "RFID intelligent batch identification access door" as the core, realizes the rapid identification of turnover packaging materials and implements, and transfers the data of the entry and exit transfer stations to the warehouse management system. The specific plan is as follows:

l Install an RFID UHF tag for each revolving packaging material container as a unique identification.

l Install the RFID intelligent batch identification channel door at the transfer point of each transit point to realize the rapid and automatic identification of turnover packaging materials.

l Real-time uploading of in-out information to the material management system.

Project application:

This project uses a total of 20 sets of RFID access doors developed and produced by sygole itself, covering 6 transit sites and more than 20,000 RFID tags.

Value gain:

Realize rapid identification of material turnover, improve logistics efficiency by 40%, and reduce labor management costs by 20%.

Core Advantages:

sygole RFID intelligent access door can support at least 150 tags for rapid identification, reducing the steps of manual recording and greatly improving logistics efficiency.

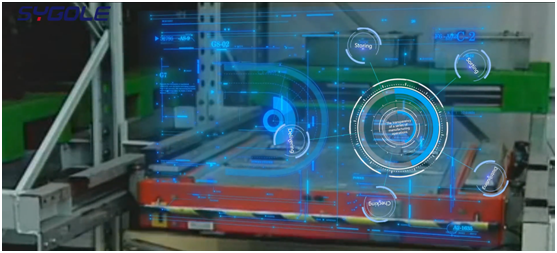

Product application pictures:

Channel door RFID UHF reader RFID channel door field application