- Home

-

Products

-

HF Series RFID Products

-

HF Integrated Reader

-

Product Model

- SG-HR-I1 HF Integrated Reader SG-HR-I2 HF Integrated Reader SG-HR-I5 HF Integrated Reader SG-HR-I6 HF Integrated Reader SG-HR-I10 HF Integrated Reader

-

HF Split Read-write Processor/Split Antenna

-

Product Model

- SG-HA-181/182 HF RFID ANTENNA SG-HA-183 HF Middle Range RFID Reader SG-HR-S1 Universal Fixed RFID Reader SG-HR-S6 Series SG-HR-S8 Series

-

Product Model

-

UHF Series RFID Products

-

UHF Integrated Reader

-

Product Model

- SG-UR-I81 UHF Integrated Reader SG-UR-I82 UHF Integrated Reader SG-UR-I83 UHF Integrated Reader SG-UR-I84 UHF Integrated Reader SG-UR-I85 UHF Integrated Reader SG-UR-I86 UHF Integrated Reader

-

UHF Split Read-write Processor/Split Antenna

-

Product Model

- SG-UR-A9 UHF Split Reader SG-UR-A10 Multi-Channel UHF Read/Write Devices(860~960MHz) SG-UR-A12 Multi-Channel UHF Read/Write Devices(860~928MHz) SG-UR-A16 Multi-Channel UHF Read/Write Devices(860~928MHz) SG-UA-271 UHF Small Universal Antenna UHF Antenna SG-UA-273 UHF Antenna SG-UA-274

-

Product Model

- Industrial Bus Gateway Module

- Industrial Code Reader

-

HF Series RFID Products

- Equipment

- Industry & Case

- News

- Service

- Company

- Details

Product Profile:

SYGOLE SG-HT-113M/114M is a high performance HF electrode tag, support ISO-15693 standard. Anti-metal design, high strength package, with IP68 waterproof protection grade, it can be directly installed on harsh industrial environment such as metal surface, moist, oil, ect. With large capacity storage, convenient for users to establish management information.

Application:

Mold/Tool management, Metal fixture management, Engine manufacturing, etc.

Features:

²Operating frequency is 13.56MHz,supporting ISO-15693 protocol

²High sensitivity,strong anti-interference ability,accurate reading/writing distance

²Large storage capacity,convenient for storage the information of managed part.

²IP68 protection grade for harsh environments,corrosion resistant cutting fluid

²Lightweight structure for easy insertion into tool holders,molds,and electrode holders

Typical Application:

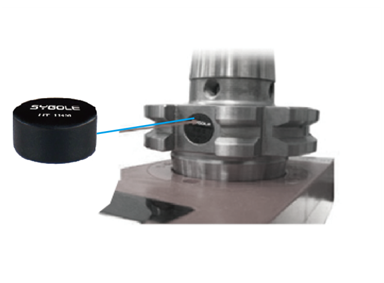

ØTool Management

For tool management of CNC machine tools,SG-HT-113M date carriers can be directly embedded in the tool and passed the dynamic balance test.Tool information such as tool number,tool parameters,and service life can be stored in the date carriers. Readers can collect tool information in the date carriers and provide it to the background processing,thereby realizing the tool life cycle management and automatic loading processing.

ØElectrode Management

For electrode management,SG-HT-110M date carriers can be screwed into the electrode holders.Electrode information such as electrode model,production state,storage location,maintenance record,and usage history are stored in the date carriers. Readers can collect the electrode information in the date carriers and provide it to the background processing,thereby realizing the life cycle management of the electrode.

Technical Parameters

HT-113M | HT-114M | ||

Wireless protocol | ISO-15693 | ISO-15693 | |

Working frequency | 13.56MHz | 13.56MHz | |

Reading distance (mm) | HR-I1 | 6-9 | 7-9 |

HR-S8+HA-181 | 12-15 | 9-11 | |

HR-S8+HA-182 | 18-21 | - | |

Storage type | EPPROM | FRAM | |

Memory | UID | 64 bits | 64 bits |

User | 112 bytes | 2000 bytes | |

Working mode | Readable/Writable | Readable/Writable | |

Data storage time | >10years | >10 years | |

Rewriting times | More than 100,000 times | More than 100,000 times | |

Physical parameters Metal resistance | Anti-metal | Anti-metal | |

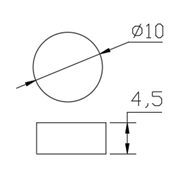

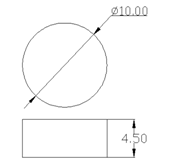

Size | Ф10*4.5mm | Ф10*4.5mm | |

Weight | 5g | 5g | |

Installation | Potted, flush or above metal surface | Potted, flush or above metal surface | |

Material | PBT | PBT | |

Color | Black | Black | |

Working Temperature | -25℃~+75℃ | -25℃~+75℃ | |

Storage Temperature | -40℃~+85℃ | -40℃~+85℃ | |

Waterproof/dustproof | IP68 | IP68 | |

Dimension drawing |

| |

Forms of Application:

The tag is installed directly into the tool, which is used to enter the relevant information of the tool model parameters, purchase date, maintenance status, etc.; it can realize the tracking of the tool's full life cycle status and understand the current status of the tool in real time;

When the tool is ex-warehouse for processing, the processing plan can be written into the tag; after the tool is put on the machine, the plan information can be directly read by the reader to realize the one-click operation of the machine tool processing;

Installation Diagram:

Tag can be installed in the tool holders,module, and fixed by special glue.